Ice Logos

These company logos were created on the CNC using a number of processes to meet the specification required.

The profiles themselves were cut out of 100mm thick Perspex with a specialist cutter that had to be run in a very specific manner, after numerous test cuts for feeds and speeds.

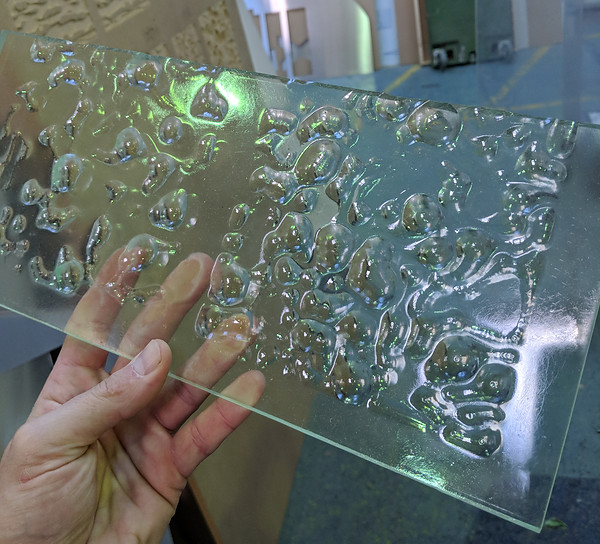

The texture was milled with a ball nose cutter after many sample cuts were provided to the client and chosen.

As some pieces had engraving, this would mean the piece would need be milled from both sides. This was achieved using a template/ jig fixed to the CNC bed.

Test cutting samples of textures provided to the client (above) and (right) a piece of milled acrylic after polishing to provide a clear finish.

As the milled texture left the surface of the Perspex frosted, and after test polishing proved to be time consuming, the pieces were finished with high quality, high clarity, UV and scratch resistant lacquer.

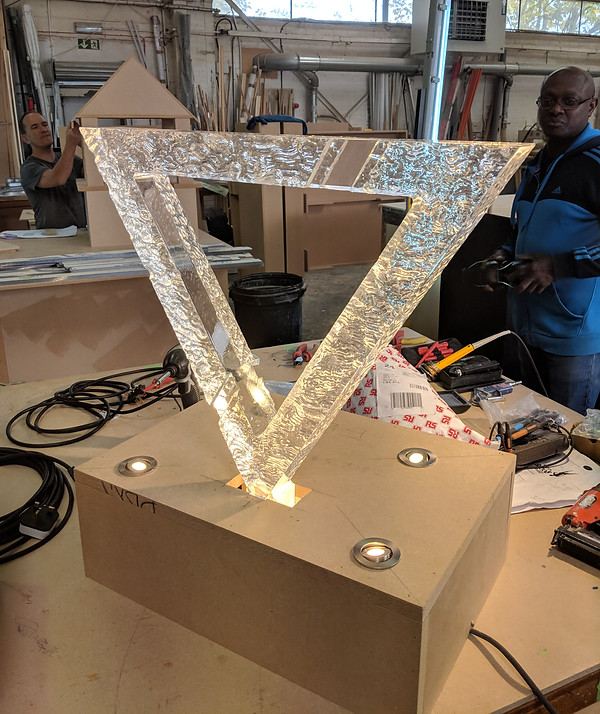

The milled texture can be seen when the piece is first taken off the CNC (left), and below the pieces in the spray shop after receiving a coat of lacquer to make them totally clear.

Each piece was mounted to a bespoke plinth that housed a plaque and up lighting.

Here you can see the spot light's position being tested to illuminate the object.